By Michael Albans, Vermont Country Magazine.

BENNINGTON — The first recorded reference to cider dates back to Roman times. Julius Caesar discovered Celtic Britons fermenting cider from native crabapples, and in northern Spain, farmers fermented apples before the birth of Christ.

In Colonial America, cider was the most commonly consumed beverage, even more than water, which was considered risky.

Pressing and fermenting fresh apple juice was the easiest way to preserve a large fruit harvest that the first colonial Americans planted. In rural communities, taxes, wages and tithes were often paid in cider.

By the late 1800s, cider began its steady decline. Several unrelated forces combined to wipe cider from the collective memory of America. A significant factor was the Industrial Revolution, bringing people from the farm to the city to live and work. Many orchards were abandoned, resulting in drastically reduced production. Unfiltered and unpasteurized cider did not travel well from farms to the new population centers. An additional element was the increased consumption of beer, especially in cities. Immigrants arriving from Germany and Ireland and cheap grain in the Midwest led beer to replace cider in the marketplace.

By the time Prohibition was enacted in 1919, the production of cider in the U.S. had substantially slipped. The once proud American tradition of cider making was kept alive by a few local farmers and enthusiasts. In recent years, there has been a resurgent interest in cider making, and today, cider is one of the fastest growing segments of the liquor industry.

Enter Little City Cider Co. in Bennington, dedicated to preserving and growing the tradition of New England cider through recipes lovingly curated by its owner, Greg Videtto.

“Well, I was always very interested in distillation,” says Greg as we sit inside his Bennington tasting room. “I had my first drink at 21 years old at Madison Brewing Company, and I always loved all the equipment. I guess I saw the trends with cider growing and had a little background with some cider, so I figured it was time. I’d been thinking about it for a long time.”

Greg spent 23 years owning a company called New England Custom Timber Frames, building custom homes from Vermont up to Martha’s Vineyard. The company had just started a big project when COVID hit, and the project fell out from underneath them. After giving the idea some thought and talking with some trusted family members and friends, Greg made the daring decision to move forward with his idea to have a hard cider company.

“This been seriously festering for probably about a year before COVID,” Greg says. “It was a kick in the butt, too, because when we finally kicked it off to go for it, we ended up getting stalled just like everybody else.”

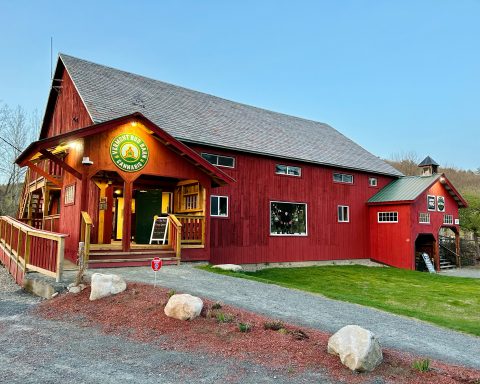

Greg found a vacant building in Bennington that had been empty for about seven years, originally housing Vermont Composites. It’s about 55,000 square feet, with the Little City Cider occupying about 1,000 square feet. That’s where his passion for cider and his experimentation with flavors began. Because of COVID, there were several delays in receiving equipment and supplies, especially his fermenting tanks from overseas, but that just gave him more time to perfect his cider recipes.

“COVID definitely made us pump the brakes a lot,” he says. “A lot of the equipment we needed ended up getting stalled. Some of the equipment was from Italy. Some of it from Germany. Some of it I got was lightly used, but we still needed a lot of parts and pieces. Moving forward, once we finally had everything we needed, we got put behind right off the bat because we couldn’t even get the apples or the juice we needed. Nobody had enough help to pick apples. They didn’t have enough help to press juice. That created a little bit of a problem.”

Little City Cider presses small amounts of apples in-house for some of its upcoming seasonal reserve cider, mostly for the fall, and receives some of its “juice” from a specialty company out of Brattleboro. The rest of its press juice, like most small and large cider companies, comes from a company in Massachusetts. During COVID, getting raw materials was a daunting task. Greg made the best of the time by perfecting the uniqueness of his ciders.

“It was probably about a year and a half making just one-to-five-gallon batches at the house at first and trying different flavors,” he said. “When we actually got fired up with this place and received our equipment, I was delighted to find that using the professional equipment was much easier and cleaner. Also, having the appropriate floor space and the drains and everything in the pumps at the new space, was great. We went from five-gallon batches to 150 to 700 gallons at a time. It was crazy.”

The Little Cider Company is currently distributed throughout Vermont, with 70 accounts, the biggest being Price Chopper.

They are currently in the process of going to Massachusetts and hope to spread their cider throughout New England.

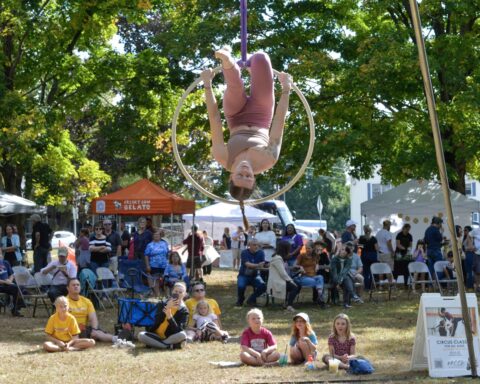

“We’re definitely not a big corporation. I’ve worked my butt off for 23 years and, pretty much at this point spent every dime I have to try to make this work because I see the growth and it’s working. There’s quite a bit of a one-man show going on here. We have a lot of volunteers that help us with our summer concerts and stuff like that. We partnered with the Vermont Arts Exchange for a concert series that’s pretty much in the winter as well. We have a really diverse crowd, and everybody’s very respectful.

They’re happy that we have a venue like this in Southern Vermont, specifically here in Bennington, with this type of atmosphere and making spirits, alcohol, cider and music. It’s a passion. I’ve always felt Vermont was a special place. I feel like people come here for a reason. Vermont itself has its own brand. I love Vermont. It’s been a huge part of my life.”

What’s really important to Greg, however, is the cider. Greg is protective of his recipe for good reason — it’s unique, a kind of champagne-type cider, semi-dry to dry, due to his use of champagne, ale and wine yeasts.

“A lot of cider is really sweet,” Greg says, “I went down the road of semi-dry to dry. And I was very happy to find out people liked it. People who tried it were like, ‘Wow, this is nice. It’s not so sweet. I can drink a few of them’ or, you know, ‘it’s not making my face pucker.’ Some of my friends that are hardcore craft beer drinkers love a cider called ‘Hopped Up.’ We infuse two different types of hops into it. They like that. It was a good twist for us.”

Little City Cider produces several other versions of cider as well.

It now has up to eight different flavors.

Videtto also plans on producing seasonal offerings in the near future when time allows.

“In the fall, we do one that’s called Seasonal Vibe. That’s a cinnamon, nutmeg, clove-infused cider. We also have a new release coming soon, which I don’t want to talk about too much because it’s going to be a surprise, but it will be probably the one sweet offering in our lineup.”

When pressed on details, Greg smiles and says, “So in Vermont, and just over the border in New York, we have a lot of different fall festivals, carnivals and fairs. It will kind of go down the lines of something that would be at those fairgrounds.”

I asked Greg to take me through the process of making hard cider, from delivery of the raw juice to filling up the cans and kegs for his tasting room.

He said it all starts by suspending the apple’s natural fermentation process so it can be controlled.

“As soon as we get that juice, we suspend the natural yeast that’s an apple so that it doesn’t start fermenting on its own. That allows me to add whatever type of yeast I would like to use to help ferment. Quite a few of our recipes have different yeasts. A lot of companies use cider-based yeast. I don’t. I use all champagne, wine or ale yeast for the majority of our ciders. The goal is to replace it so that you add what you want it to taste like. Champagne yeast will dry it out pretty good. Some of these other ale and wine yeasts I use have a nice finish.”

It takes about 48 hours to suspend the yeast, producing about 6% alcohol within a couple of weeks. The whole process, from start to finish, takes 60 to 90 days.

“Cider is very different than beer. We skip the whole boiling process. Cider is ultimately a wine. We basically have a wine license to make cider. Cider is very much like wine in the sense the longer it sits, the longer it ages. Maybe not everybody that makes hard cider would agree with me on that, but you know, it usually smooths out, and it also clarifies it. People say, ‘Oh my goodness, this looks so clear. You must filter it.’ Our ciders are unfiltered, but because of our process, it naturally cleanses itself by settling the suspended particles over 60 to 90 days in the tank.”

Greg points to one of the giant vats lined up across the back wall of his tasting room. Each tank funnels down into an upside-down cone. He says the shape of the tank allows him to remove the unwanted particles without losing flavor or color. The apples and juice have already been pasteurized, avoiding unwanted elements in the cider.

“When you look at cider and get one in a gallon jug, that’s just normal cider. It’s brown, right? That’s what the juice looks like when I get it. It’s basically an oxidation. You cut an apple on your countertop, and you turn it on, wash your hands, and you come back, it’s already starting to brown. It’s an oxidation process. My semi-dry is as clear as a Chardonnay. The sediment goes down to the bottom of the tank, into those cones right there, that would be called a cone. We have a valve on that. I let it sit so it clarifies. These tanks are jacketed with glycol jackets so that I can control the temperature. My different recipes have different fermenting temperatures, as they do finish temperatures. Once we get to a certain point, and I get the sediment out of the bottom, when I close that valve, and I’m happy. You’re looking for clarity that’s fermenting all this time. It gets to the point where you are happy with both the clarity and the alcohol content.

“We then chill it down to, say, 34 to 35 degrees. That also helps clarify because that will drop that last little bit of sediment out.”

“From that point, we’ll carbonate the cold, chilled, clarified product in the fermenter. Almost every one of these fermenters can do the whole process. Depending on the recipe, there’s more or less carbonation. Once it’s carbonated, I add fresh press purees out of California. That’s where the flavor comes from. It takes 60 to 90 days for the process — from apple juice to drinking at our tasting room.”

Little City Cider Co. looks forward to distributing its cider throughout New England but wants to remain close to its roots.

“I don’t see it getting too big. I like the Vermont roots thing. I see potential growth, needing bigger equipment and such. I mean, we already need bigger equipment. How big? I don’t know. I’m trying to get this off the ground where maybe we feel comfortable getting bigger equipment down the road. We are small. It was a dream, and we’re following it, and life’s good and happy. It’s good stress.”

Little City Cider Co. is at 139 Shields Drive in Bennington. It is open year-round, three days a week, Thursday, Friday and Saturday, from 5 p.m. till closing. The site hosts a concert series once or twice a month, and also hosts local musicians and an open-mic night twice a month.

“Everybody has been very supportive of this. We are trying to create a venue space with what we have to share here and use it to have these events. Music is a huge passion of mine. I love music. That’s my church. And I love being able to put on a show for people. There have been no problems. You don’t come in here and see people all drunk. You see people enjoying themselves, listening to music and having a few cocktails.

“I am so very thankful for the support from the town and everyone.”

Michael Albans fancies himself a Brooklyn ruffian but is really a Pee Wee Herman and Barney mashup with a bad attitude. Mike takes nice photos and writes about most anything besides the outdoors or clothing trends. He has no friends but loves his wife.