Preserving the craft of traditional butchery at Sutter Meats

Photo by Sarah Crosby

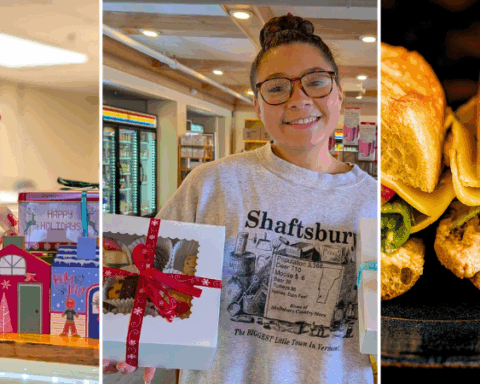

Sutter Meats butcher and owner Terry Ragasa, center, works with a 210-pound pig from Sage Farm in Montague, Mass., during a pork fabrication class at the Northampton business. Class attendees Abby VanderLinden, of Sunderland, left, Sam Reed, of Sunderland, and Nolan Southard, Andy Smith and Ben Boehm, all of Pittsfield, follow along.

By Hunter Styles

Terry Ragasa takes a deep breath before he lifts the pig from its hook. It has been hanging in a walk-in cooler at Sutter Meats in Northampton, Mass., kept company in the dark by its sustainably raised, locally slaughtered kin.

The inside of the cooler doesn’t allow Ragasa much room to maneuver an animal nearly as big as himself, but this isn’t his first rodeo. He checks and tightens his grip, then hefts the pig high enough to carry it down a short corridor, without touching hoof to floor.

His six students for the day, myself included, follow him to the broad wooden table in the sunny front room of the butcher shop, where customers browse the fridges and cases. Anyone can peer past the main counter, if they like, and watch it all play out: this job of breaking down a large animal, turning it into wrapped cuts of meat under glass.

The pig in Ragasa’s arms used to live a 25-minute drive north of here, on a 90-acre plot in Montague, Mass., called Sage Farm, which produces pastured heritage breed pork. This sow, a mix of Berkshire and Tamworth breeds, foraged and grazed her way to 200 pounds over about eight months.

Today, we are only fabricating one side of the pig, following the grain of the meat fiber and breaking down the carcass into specific cuts, guided by thick versus thin and tender versus tough. This is a traditional technique called “seam butchery,” in which a butcher works by separating whole muscles and muscle groups, maintaining much of the anatomy and integrity of the animal as it comes apart.

A model pig displays different cuts of pork.

Ragasa has been leading this demonstration since 2014 when he opened Sutter Meats on King Street with his wife and business partner Susan (the word “Sutter” is a combination of the couple’s first names). This two-hour pork butchering class is held twice a month year-round on Saturday afternoons.

Students at the six-person class, which costs $100 to attend, each take home a small bag filled with mixed pork cuts. But the demonstration itself is a real treat: an interactive opportunity to meet your local butcher, see where your meat comes from, ask questions and collect a few culinary pointers.

While the class draws many visitors unfamiliar with Sutter Meats, it points clearly to the ethos of this shop, which prides itself on small-scale quality control, and strong local relationships with family farms and restaurants in the Pioneer Valley.

It is telling that the Sutter Meats webpage describing the shop begins with a quote from the farmer-poet and activist Wendell Berry. “I dislike the thought that some animal has been made miserable to feed me,” Berry wrote in “What Are People For?”

“If I am going to eat meat, I want it to be from an animal that has lived a pleasant, uncrowded life outdoors, on bountiful pasture, with good water nearby and trees for shade.”

When Terry Ragasa lays this pig down, it lands with a heavy slap on the butcher block, and the class seems to instinctively pause for a moment, reflecting on the sacred and somewhat mysterious task in front of us. Then Ragasa gets to work, methodically pointing out the bones and joints, tendons and ligaments, fat deposits and muscle groups — the architecture of this feast.

Using a boning knife and a hacksaw, Ragasa spends two hours leading us through a process that typically takes him 15 minutes. As he detaches each cut, from pork shoulder to ribs to loin to legs, conversation shifts from the history of livestock to international butchering styles to standards in the restaurant industry.

Some of Ragasa’s notes are specific, such as grilling and cooking tips for certain cuts. Other thoughts are broad but equally helpful, like the observation that a cut of pork or beef is usually less tender the further forward on the animal it is found, and the closer it is to the ground.

Students are here to observe since working hands-on with these tools is a liability issue — something Terry and Susan Rasaga are discussing for their next insurance plan. Sutter Meats also offers private classes for anyone interested in purchasing a pig, then working side by side at this table to learn butchering firsthand.

After the class, Ben Boehm tells me that his wife signed him up as a Father’s Day gift. Boehm lives in Pittsfield and has spent half his life managing restaurants, including seven years at Bistro Zinc in Lenox. Now, he’s at home, raising his kids.

“But I cook at home, so this is great,” he says. “You learn a lot just being in the restaurant business, but to do something like this is instructive and informative.”

Nolan Southard, also from Pittsfield, says he grew up hunting and that “as he’s talking about cuts, I’m thinking about what I would do with a deer or a moose. It’s helped me to see things differently. And it’s such a great model — he’s just performing his job, and everyone else benefits by watching.”

Abby VanderLinden is a graduate student in Biology at the University of Massachusetts-Amherst. She signed up immediately once the fall pork classes were announced in the Sutter Meats newsletter. VanderLinden is a mammal anatomist, and works on animal specimen prep for labs and museums.

“It takes such skill to do this in a usable way,” she says. “I just wanted to see the process. What does it involve when you’re trying to do it deliberately, and take good care?”

In all endeavors, from sausage to deli meats to charcuterie to bone broth and stocks, Sutter Meats hopes to narrow the gap between eater and food source. Classes are part of that mission, and Terry Ragasa doesn’t seem surprised by the varied backgrounds of those who sign up.

“We get curious foodies, but a third of the people who take the class are small farmers or homesteaders who want to get the most out of their animal,” he says. “This helps them talk to their processors, so they can make more profit from what they’re raising.”

“We also get people who work in restaurants, either on the line or as a chef,” he says, “who want to change or augment their existing meat program to make it more sustainable.”

“Our whole process is about transparency,” says Susan. “Terry and I take care when we’re selecting and working with the farms, and that leads into our customer service. It’s something that people can’t really get from a large grocery store. We talk with our customers and answer questions, and we always see light bulbs going off in their heads.”

“This business requires knowledge on the part of our customers,” says Terry, “but it also requires patience from us. We offer some unusual cuts, and people see things in the cases they’re not familiar with. We help them understand what we’re selling. If you understand the sacrifices being made by farmers and animals that leads to the food on your plate, you become a better and more conscious eater.”

Sutter Meats

65 King St., Northampton, Mass.

Open 10 a.m to 7 p.m. Monday to Friday; 9 a.m. to 5 p.m. Saturday and Sunday

More information: 413-727-3409, suttermeats.com

If you are a local farmer interested in selling meat at the store, email Terry Ragasa at butcher@suttermeats.com.

Upcoming:

Pork Fabrication Class

When: Saturday, March 30, 1 to 3 p.m.

(Additional classes available on April 6 and 13 and May 4 and 18)

Classes are limited to six people and fill quickly. Call for general store and class information or email info@suttermeats.com.

Hunter Styles lives in Northampton, Mass., where he has worked as the arts editor of the Valley Advocate and editor of Preview Massachusetts. His column The Beerhunter runs monthly in the Valley Advocate.